SMD contact pads, fully known as Surface Mounted Device Contact Pads for Printed Circuit Boards (PCB), are critical electronic components widely used in electronic devices.

SMD contact pads mainly use high-quality copper alloy materials as the base material. This is because copper alloys have good electrical conductivity and mechanical properties, which can ensure stable current transmission and reliable connections of components. During the manufacturing process, the copper alloy materials are precisely machined into form through a precise turning process according to strict design dimensions and shape requirements. The thinnest thickness is only 0.15mm to meet the installation and electrical performance requirements of different electronic circuits.

After processing, key electroplating processes are also required. Specific metal coatings such as nickel, gold, and palladium are typically used for electroplating. Nickel plating can improve the solderability of the pads, allowing the components to better fuse with the solder during the welding process, ensuring the firmness and reliability of the welding; while gold plating can enhance the oxidation resistance and wear resistance of the pads, and further improve their electrical performance, making them especially suitable for high-end electronic devices that require high reliability and signal transmission quality. SMD contact pads are packaged using advanced vacuum carrier tape packaging methods. After vacuuming to isolate oxygen, moisture, and dust, they are heat-sealed, ensuring moisture-proof, dust-proof, and anti-oxidation during storage, providing cushioning and shock absorption during transportation, and are compatible with automated production lines to ensure product quality and efficient production.

After the aforementioned rigorous manufacturing processes, SMD contact pads can be widely used in various electronic products such as smartphones, tablets, laptops, and various precision electronic instruments, playing an indispensable role in modern electronic industry.

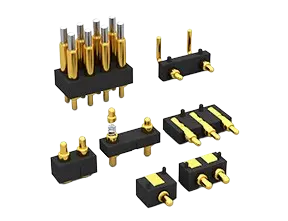

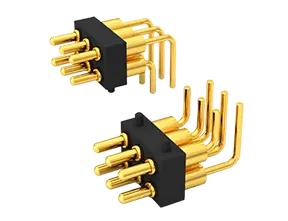

Related Pogo Pin Connectors

Pogo Pin Connectors Related News