Through long-term technical exploration, research and accumulation, Rtench has achieved a high quality level in the plating of nickel, gold, platinum, copper, tin, silver and nickel-free plating of hardware terminals, especially in vacuum blind hole plating technology.

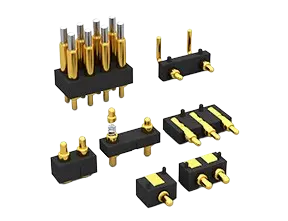

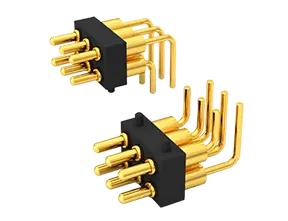

The surface electroplating process is the core of the Pogo Pin Probe Spring Connector. Rtench continues to invest in imported equipment and develop together with partners. At the same time, through long-term technical exploration, research and accumulation, we are currently engaged in the plating of nickel, gold, platinum, copper, tin, silver and nickel-free plating of hardware terminals, especially in vacuum blind hole plating technology. High-quality level. The use of high-quality imported formula materials and advanced vacuum blind hole electroplating process can ensure that the inside of the blind hole of the needle tube is gold-plated and golden and bright. High-quality materials and advanced vacuum blind hole electroplating process can obtain stable contact resistance, longer life, and higher corrosion resistance. The company has repeatedly undertaken research and development research and cooperation in scientific research institutes, research institutes, large listed companies, electrochemical corrosion-resistant new electroplating materials and new processes, and surface treatment of 5G product materials, and has become the preferred partner of some well-known international and domestic companies.

The materials selected by Rtench comply with EU RoHS requirements. The materials are sent to the authoritative certification body SGS Switzerland for RoHS testing and certification every year. The environmental protection indicators meet the standards of Japan, Europe, America, and China.

Mature and stable vacuum electroplating process, as excellent as the electroplating of very thin blind holes, the inner hole is golden and bright.

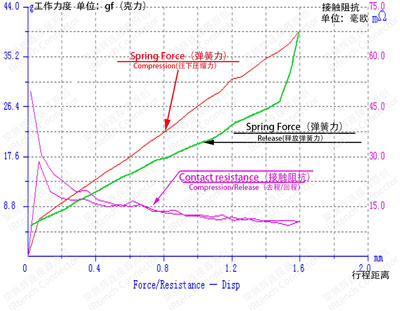

Advanced and stable vacuum plating process to obtain stable and extremely low contact resistance.

Related Pogo Pin Technology

Rtench's Pogo Pin Connectors News