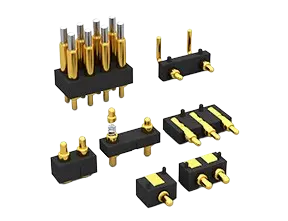

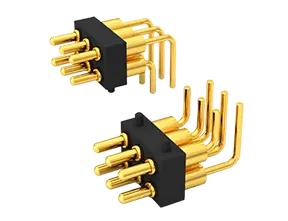

Rtench, one of leading and professional pogo pin manufacturers, uses such waterproof technologies as in-mold injection molding, adding O-rings, dispensing waterproof glue and pin needle hot-melt glue and others to meet waterproof requirements.

1. The Pin needle clamp is inserted into the female (male) end of the housing mold for integral injection molding, and the integrated injection molding is inserted into the mold to achieve IPX7 waterproof, referred to as INSERT MOLDING;

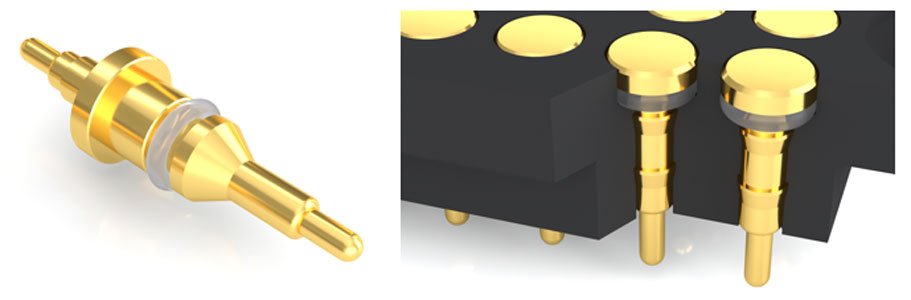

2. The O-shaped sealing ring is combined with the Pin needle and pressed into the plastic hole, and the gap is filled with the O-shaped sealing ring through size interference to achieve IPX8 waterproof, referred to as the O-ring interference method;

3. Heat the Pin needle to a certain temperature and push it into the plastic hole under pressure to achieve IPX7 waterproof, referred to as the hot-pressing and melting glue method;

4. On the basis of the in-mold injection molding method, hot pressing melt method, or O-ring interference method, add waterproof glue (automatic glue dispenser dispensing), which can reach IPX8 waterproof.

Now more and more smart wearable electronic products have waterproof requirements. The waterproof level has become higher and higher from the initial IPX6 to IPX7 and IPX8. Rtench pogo pin types use in-mold injection molding, adding O-rings, dispensing waterproof glue and pin needle hot-melt glue and other waterproof technologies to meet waterproof requirements. In order to ensure the quality, the products in the mass production process have been tested for air tightness (leakage test)

Pin needles are clamped into the female housing mold to form an integral injection molding, and then water-proof glue is applied to achieve IPX7 waterproof.

The pin needle is clamped into the female housing mold to form an integral injection molding, reaching IPX7 waterproof.

Pin needles are clamped into the female (male) end of the casing mold to form an integral injection molding, reaching IPX7 waterproof.

The pin needle and O-ring are combined together and pressed into the plastic hole, and the gap is filled with the size interference and the O-ring to achieve IPX8 waterproof.

Related Pogo Pin Technology

Rtench's Pogo Pin Connectors News