Pogo Pin Connector: The secret behind 100,000 insertions and removals and life analysis

In the electronic equipment industry, connector stability and longevity are crucial. Pogo Pin connectors are widely used in many applications as an efficient and reliable connection solution. Today, we will take an in-depth look at the 100,000 mating cycles and lifespan analysis of Pogo Pin connectors.

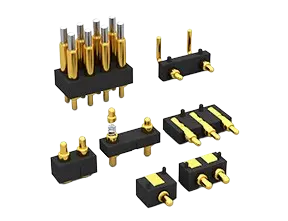

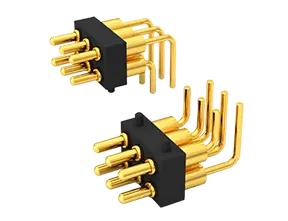

The Pogo Pin connector is a unique connector that consists of a pogo pin and a spring. The up and down movement of the pin enables the circuit to be switched on and off. Due to its compact structure, low contact resistance, and fast transmission speed, Pogo Pin connectors are widely used in many high-precision electronic devices.

The 100,000 mating and unmating times of the Pogo Pin connector is based on comprehensive consideration of its materials, design and manufacturing process. First, high-quality spring materials and precise manufacturing processes ensure the elasticity and durability of the needle. Secondly, the reasonable structural design allows the needle to always maintain good contact with the contact surface during the insertion and withdrawal process, reducing wear and stress concentration. In addition, strict quality control and durability testing are also important guarantees to achieve 100,000 plugging and unplugging times.

For the life analysis of pogo pin connectors, we need to consider multiple factors. First, the choice of materials has a crucial impact on lifespan. High-quality spring materials and stable manufacturing processes can significantly increase the life of the connector. Secondly, the usage environment and usage methods will also have an impact on the life of the connector. For example, frequent plugging and unplugging, excessive plugging and unplugging force, or use in harsh environmental conditions may accelerate connector wear.

In order to ensure the service life of the Pogo Pin connector, we recommend that users maintain appropriate plugging and unplugging force during use, avoid use in harsh environmental conditions, and perform regular maintenance and inspections. At the same time, we, as one of leading and professional pogo pin manufacturers, will continue to optimize materials, design and manufacturing processes to further improve the life and stability of Pogo Pin connectors. To complete the comprehensive subject of 100,000 mating and unplugging times and lifespan analysis of Pogo Pin connectors, we must comprehensively consider multiple aspects such as materials, design, manufacturing, use and maintenance. Through continuous in-depth research and innovation, we are committed to providing more stable and reliable Pogo Pin connector solutions for the electronic equipment industry.

Pogo Pin Connectors Related News