In the field of electronic connectors, pogo pins are widely used in various devices due to their unique elasticity and stability. As pogo pin manufacturers, we understand the importance of quality control, which is not only a guarantee of product quality but also the cornerstone of our company's reputation and sustainable development. Here, we will discuss the four pillars of quality control for pogo pin manufacturers.

High-quality raw materials are the prerequisite for producing high-quality pogo pins. We insist on selecting raw materials that meet industry standards and establish long-term cooperative relationships with reliable suppliers to ensure the stable supply and excellent quality of raw materials. Additionally, we conduct strict testing and screening of each batch of incoming raw materials to ensure that their performance parameters meet production requirements.

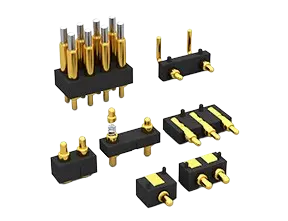

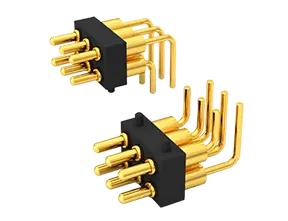

The production process of types of pogo pins requires precise process control. We have advanced production equipment and a skilled technical team that can accurately control key indicators such as the size, elasticity, and durability of pogo pins. By optimizing the production process, we reduce errors and waste during production, improving the pass rate and stability of the products.

Quality inspection is a crucial step in ensuring the quality of pogo pins. We have established a comprehensive quality inspection system, including appearance inspection, size measurement, elasticity testing, and durability testing. Through strict quality inspection, we can promptly identify and address any problems or deficiencies in the products, ensuring that every product leaving the factory meets relevant standards and customer requirements.

Quality control is an ongoing process of improvement and innovation. We closely monitor market trends and customer needs, continuously collecting and analyzing customer feedback to understand the performance of our products in practical use. At the same time, we actively introduce new technologies and materials, optimizing production processes and product designs to enhance product performance and quality. Through continuous improvement and innovation, we are committed to providing customers with superior pogo pin products.

In conclusion, as pogo pin manufacturers, we deeply understand the importance of quality control. By implementing strict raw material quality control, exquisite production process control, a comprehensive quality inspection system, and continuous improvement and innovation, we continuously enhance product quality and market competitiveness. We believe that only by focusing on quality can we earn the trust of our customers and the recognition of the market.

Pogo Pin Connectors Related News