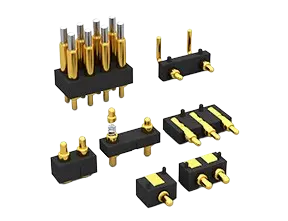

In PCB design, selecting appropriate pogo pin connectors is crucial for ensuring circuit stability and reliability. In recent years, surface mount pogo pins, known for their unique design and excellent performance, have found widespread application in PCB design. This article explores the four major advantages of using surface mount pogo pins in PCB design.

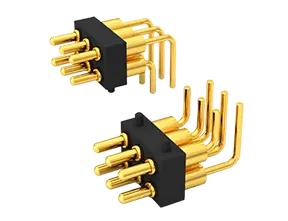

Surface mount pogo pins achieve stable and reliable electrical and mechanical connections with PCBs or other connector components due to their unique flat surface design and spring mechanism. The spring structure ensures tight contact even with minor displacements or vibrations, thus preventing electrical faults due to poor contact. This superior connectivity performance is essential for ensuring PCB stability and reliability.

Surface mount pogo pins facilitate efficient and precise installation through automated production lines, thanks to their surface mount technology. Compared to traditional connector installation methods, surface mount technology significantly reduces installation time and costs, thereby enhancing production efficiency. Additionally, the flat design allows easy removal from PCBs, facilitating maintenance and replacement and improving PCB maintainability.

Space is often a precious resource in PCB design. The surface mount pogo pins, with their flat design, enable high-density layout of connection points within limited PCB space. This design not only saves space but also increases PCB integration, allowing more electronic components to be integrated into smaller circuit boards. This is crucial for achieving more complex and compact electronic devices.

Manufactured from high-quality materials and processed with precision manufacturing techniques, surface mount pogo pins exhibit excellent durability and reliability. The spring structure withstands repeated pressures and vibrations, supporting insertion and withdrawal cycles ranging from 1 to 10 million times or more. This ensures stable performance even under prolonged and high-frequency use, thereby extending the PCB's operational life. Additionally, encapsulating the Pin pin in a plastic housing effectively prevents dust and impurities from entering, further enhancing connection stability and reliability.

In conclusion, surface mount pogo pins offer outstanding electrical and mechanical connectivity performance, efficient installation and removal, space savings, increased integration, as well as excellent durability and reliability in PCB design. These advantages make surface mount pogo pins an indispensable component in PCB design, providing robust assurance for the stability and reliability of electronic devices.

Pogo Pin Connectors Related News