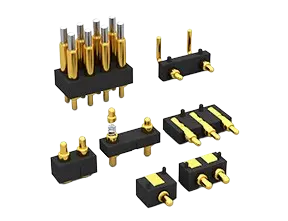

Pogo pin is a type of micro-connector widely used in various fields. It has the advantages of small size, high reliability, and low cost, making it widely used in many industries. Today, Rtench will focus on introducing different types of pogo pins and their respective functions.

The flat bottom pogo pin is specifically designed for Surface Mount Technology (SMT) and is renowned for its compact size and high automation compatibility. These types of pogo pins are widely used in portable electronic devices such as smartphones and tablets, serving as key components for signal transmission and charging interfaces. The flat bottom design facilitates precise mounting through automated production lines, ensuring consistency and reliability of the connections.

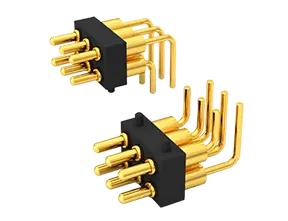

The bent pogo pin, with its specific angled bend design, addresses the challenges of spatial layout. These types of pogo pins are commonly seen in electronic devices that require space-saving or specific angle connections, such as wearable devices and small sensors. The bent structure not only optimizes space utilization but also maintains the original high reliability and conductivity of the spring pin.

The double needle axis pogo pin features a unique dual-head design, providing bidirectional spring contact. It is suitable for applications requiring redundant connections or bidirectional signal transmission. The design of such pogo pins enhances the stability and reliability of the connection, making them particularly suitable for medical equipment, aerospace control systems, and other scenarios that demand exceptionally high connection quality. The double needle axis structure ensures a stable electrical connection even in harsh environments.

The threaded pogo pin combines the flexibility of spring pins with the robustness of threaded connections, making it suitable for environments requiring high mechanical stress. These types of pogo pins achieve reliable mechanical fixation and electrical connection through their threaded structure, commonly used in industrial equipment and outdoor communication base stations that require long-term stable operation and face complex environmental challenges. The advantages of the threaded design lie in its strong resistance to vibration and loosening, ensuring enduring stability of the connection.

The above four types of pogo pins, each with its unique design and application advantages, meet the connection needs in different fields and scenarios, becoming indispensable key components in modern electronic devices.

Pogo Pin Connectors Related News