Innovative design: Slope Structure Design, More Stable Contact, Lower Resistance

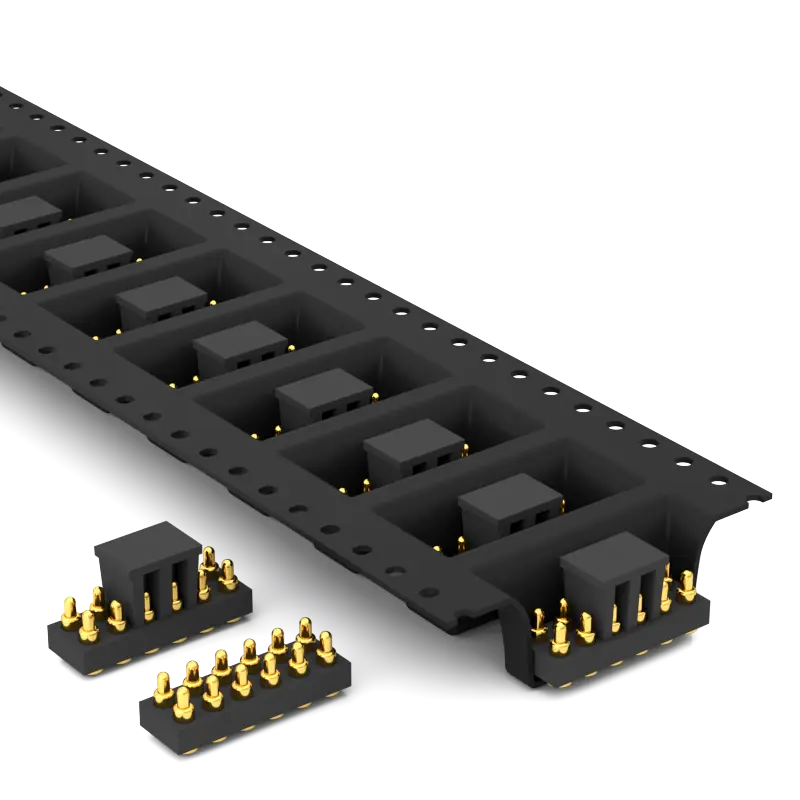

Installation method: SMT Surface Mount (SMD) Reflow Soldering or Placement by Insertion Machine and Fixation by Wave Soldering

Contact Resistance: 30 milliohms Max.

Rated Current: 10A-30A (Continuous Current)

Rated Voltage: 36V AC/DC

Durability: Min.10,000 Times (Reciprocating Motion Lifespan)

Operating Temperature: -40°C to +120°C (Continuous Temperature)

Salt Spray Resistance 96 Hours Corrosion Test

High-Precision Mold And Parts Processing

A variety of standards are available, and samples will be sent out as soon as the same day.

Provide Customized Services

Comply With EU RoHS And Reach Standards

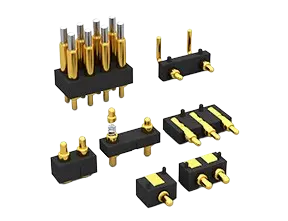

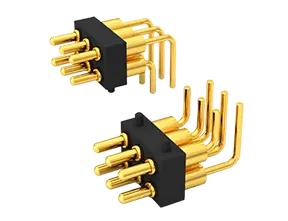

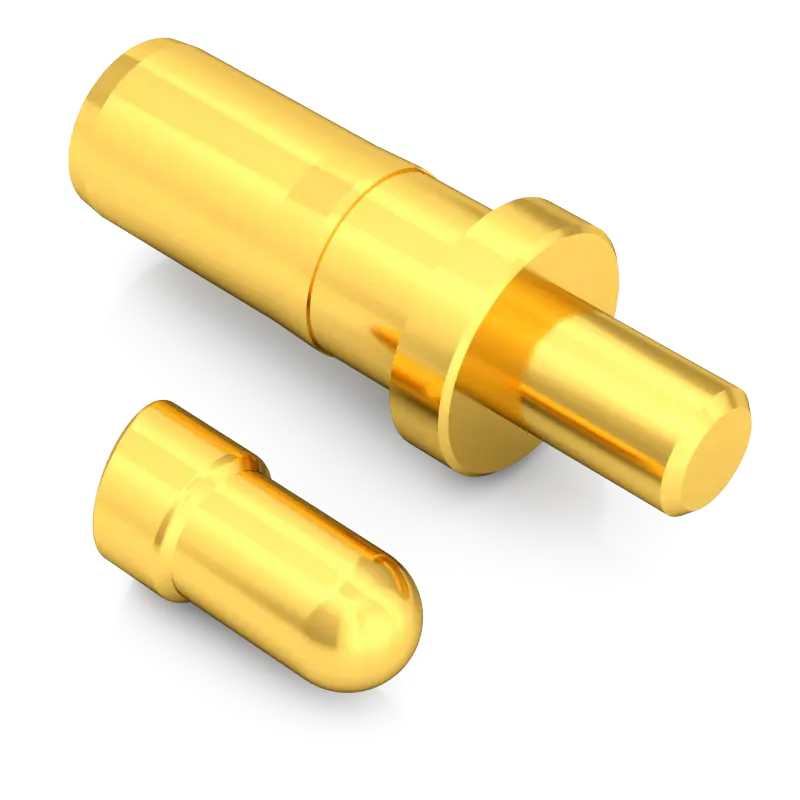

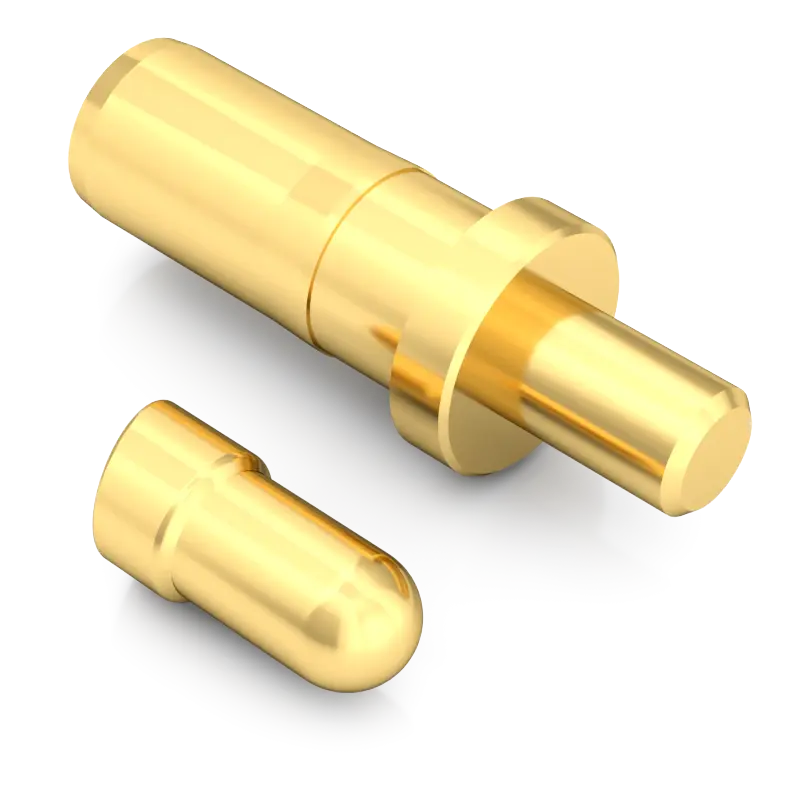

High Current Pogo Pin is also called spring pin, current pin, Pogo Pin connector, Spring-loaded Pin. It has two types: High Current SMD (circuit board surface mount) Pogo Pin and High Current Dip (plug-in) Pogo Pin. The core function of High Current Pogo Pin is high current transmission.

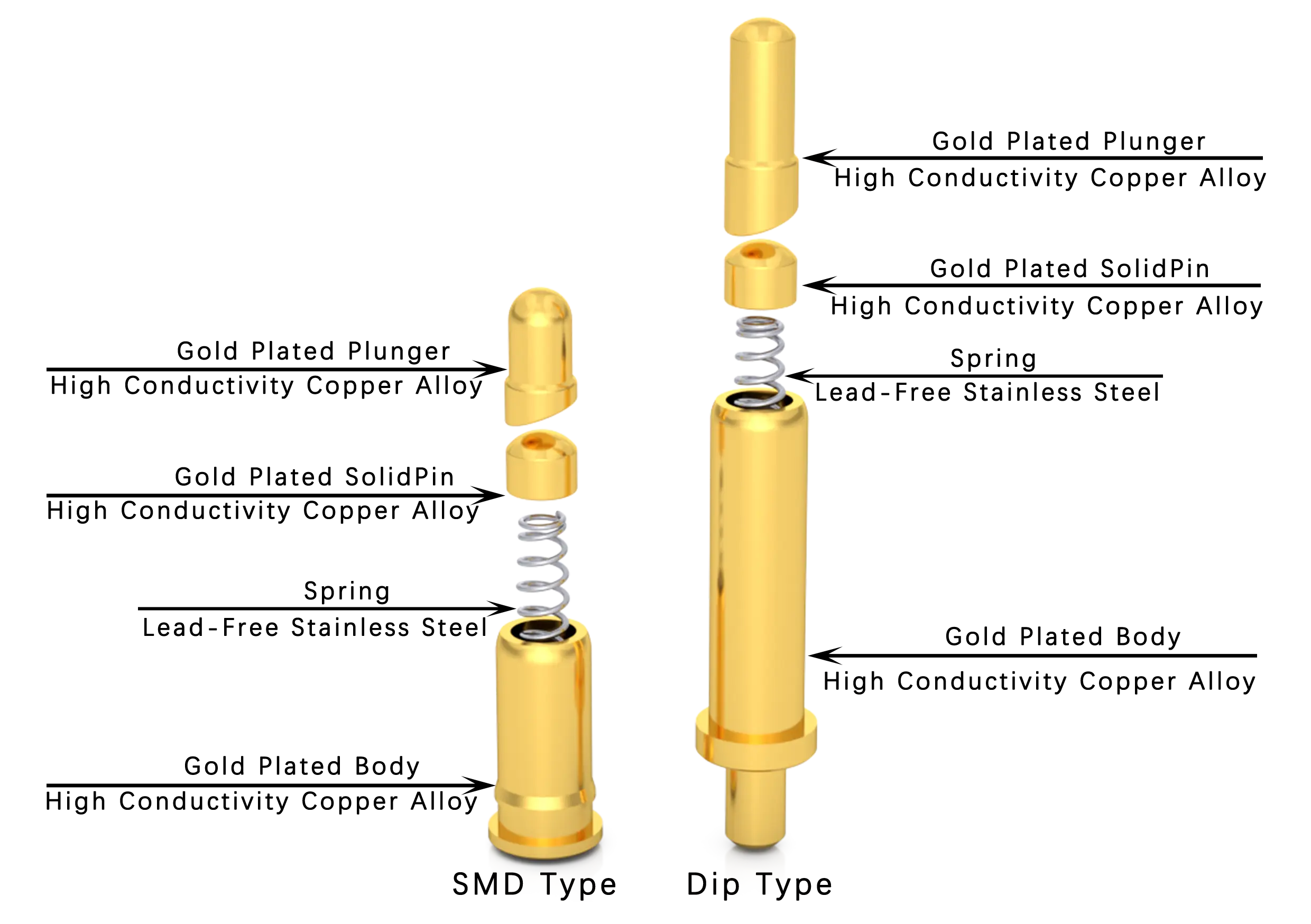

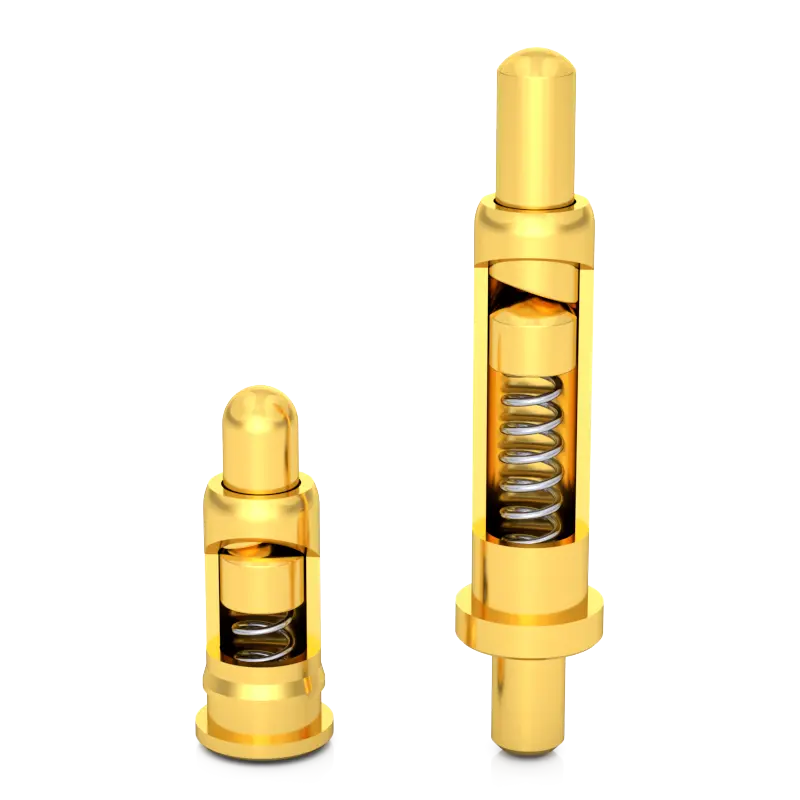

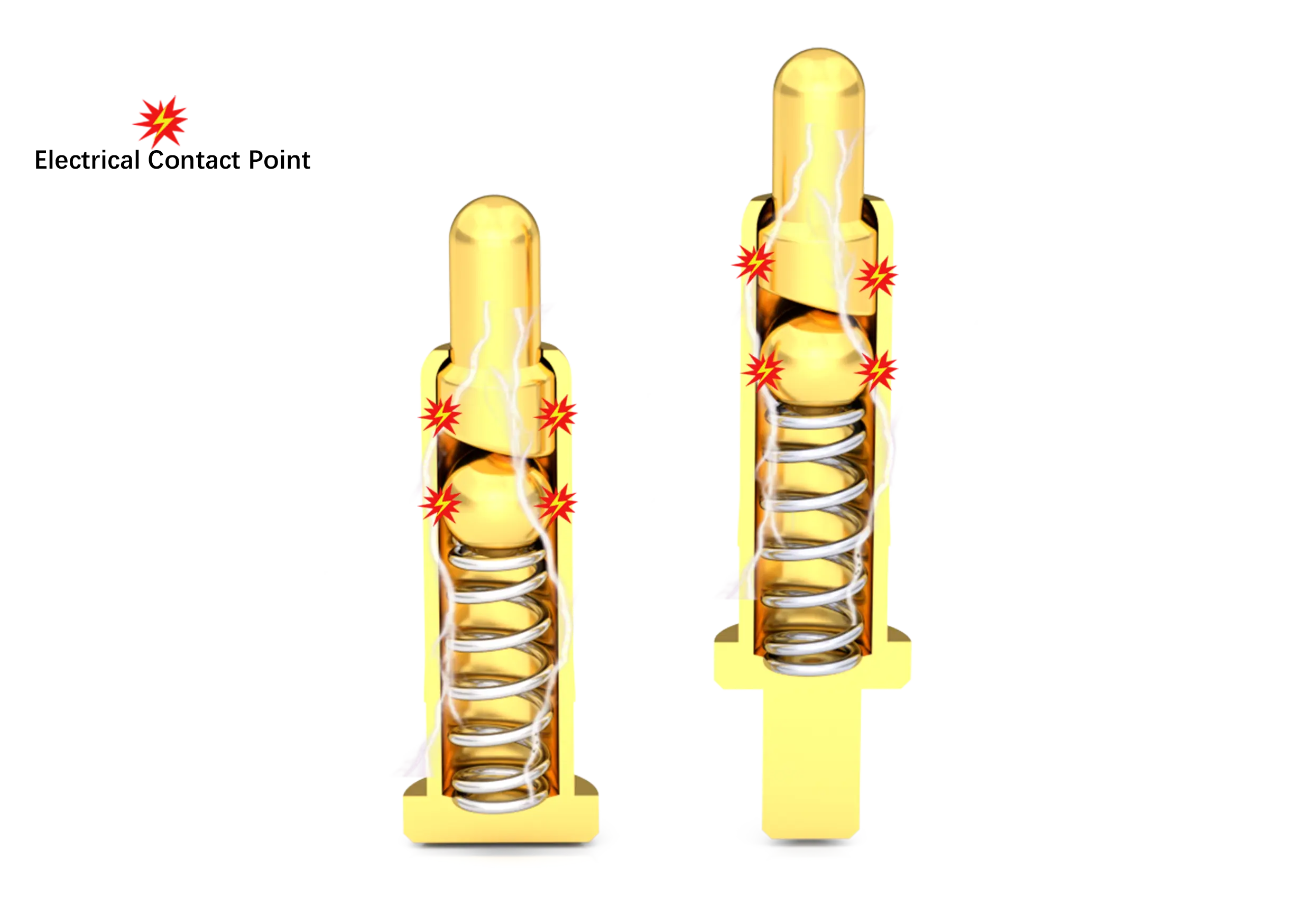

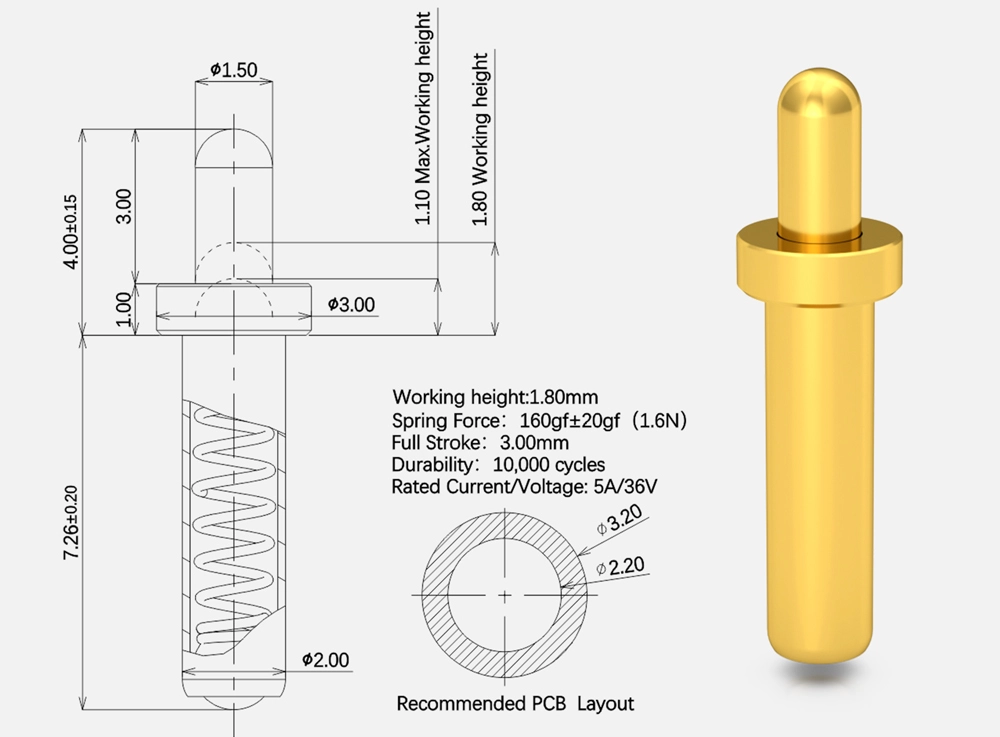

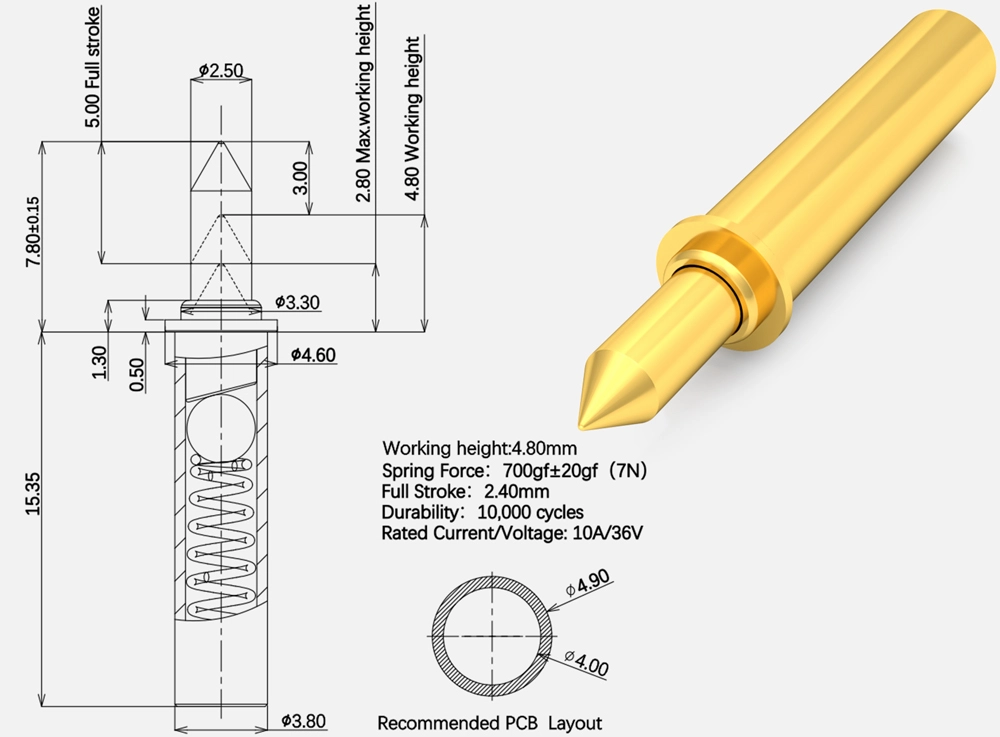

High Current Pogo Pin is designed with a bevel structure and built-in spring mechanism. It is mainly composed of three core components: Plunger, solidPin, Spring and Body, and is assembled through precision molds and special equipment. The role of the bevel structure design is to ensure that when the Pogo Pins are working, the lateral force generated by the contact between the bevel and the spring is used to maintain a stable contact force between the needle and the inner wall of the needle tube, prompting the current path to mainly pass through the gold-plated Plunger and Body, thus achieving stability And with extremely low contact resistance, it can maintain a stable and reliable connection even during frequent plugging and unplugging. The purpose of adding SolidPin is to increase the current path, improve transmission efficiency, and achieve high current transmission.

SMT automatic patch reflow technology: The SMT automatic patch machine automatically mounts the High Current Pogo Pin onto the PCB circuit board with solder paste printed on it, and then melts and solidifies the solder paste through the reflow soldering process to complete the bonding with the PCB pad. Fixed connection. This process is fast, highly precise and highly automated, which greatly improves production efficiency and product quality. High Current SMD Pogo Pin and some models of High Current Dip Pogo Pin can be installed through the SMT automatic patch reflow soldering process.

Plug-in machine + wave soldering technology: The automatic plug-in machine automatically mounts the High Current Pogo Pin and accurately inserts the solder pins into the PCB circuit board with printed solder paste, and then melts and fixes the solder paste through the wave soldering process to complete soldering to the PCB fixed connection to the disk. The process is fast, accurate and highly automated, greatly improving production efficiency and product quality. Suitable for electronic components with extremely long solder legs that cannot be fixed through SMD reflow soldering

High Current Pogo Pin is a classification of Pogo Pin connectors, with two types: SMD surface mount type and DIP insertion type. This is a built-in spring connector designed and manufactured based on a bevel structure. It usually consists of four core parts: plunger, solidPin, spring and body. Its features include high conductivity efficiency, adaptability to high current transmission, body with solder legs, precise positioning, extremely low resistance, stable and reliable connection, long life and durability.

High Current Pogo Pin adopts Plunger slope + Solid Pin auxiliary block structure design.

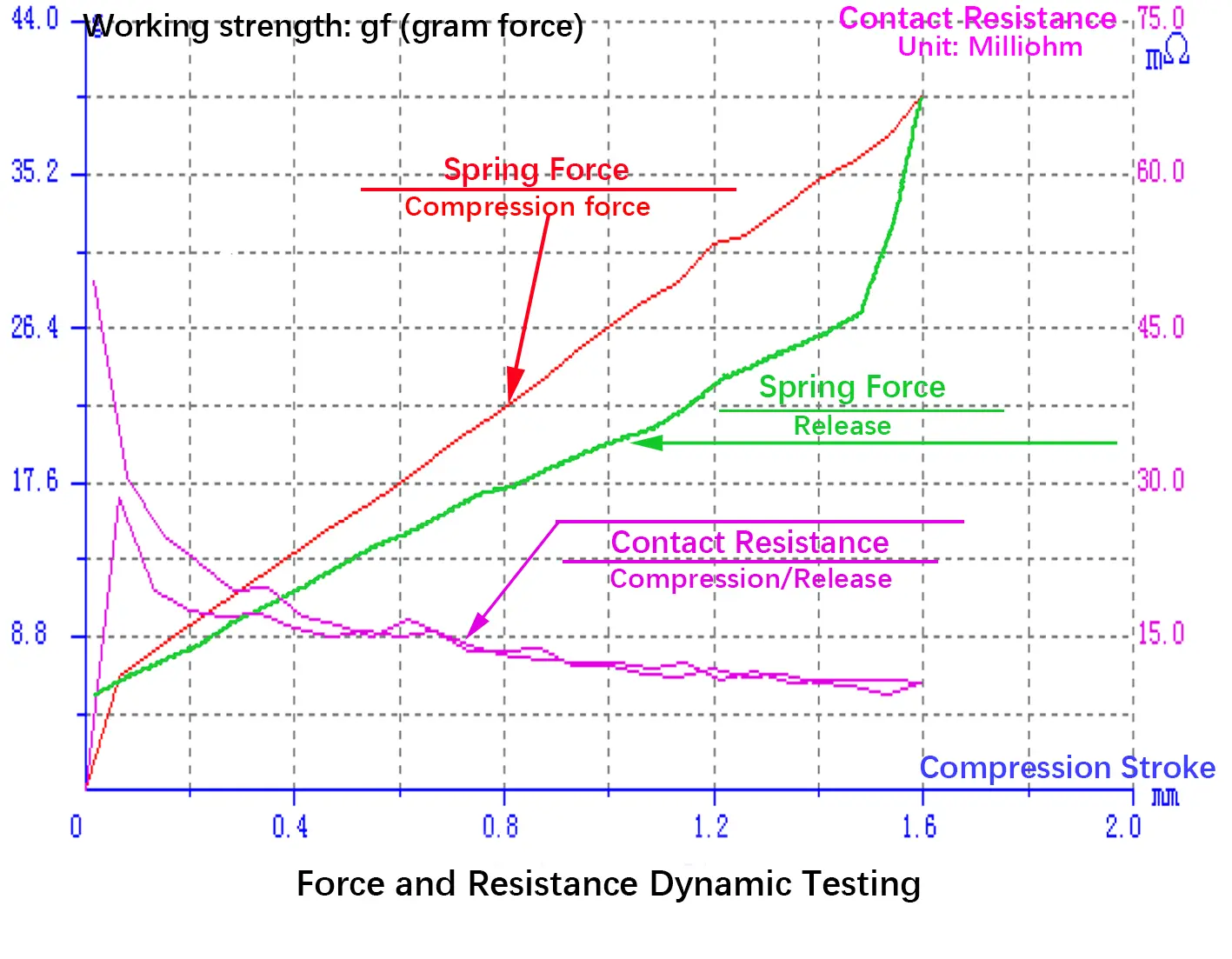

Contact force and contact resistance are the core factors for stable and reliable connections, and there is a direct relationship between contact force and contact resistance. Increasing contact force can effectively reduce contact resistance. Therefore, achieving stable contact force and contact resistance is key to establishing a reliable connection.

When the bevel and spring are working, the lateral force generated is converted into contact force, allowing the gold-plated needle to maintain stable contact with the inner wall of the needle tube, thereby obtaining stable and extremely low contact resistance, ensuring a stable and reliable connection.

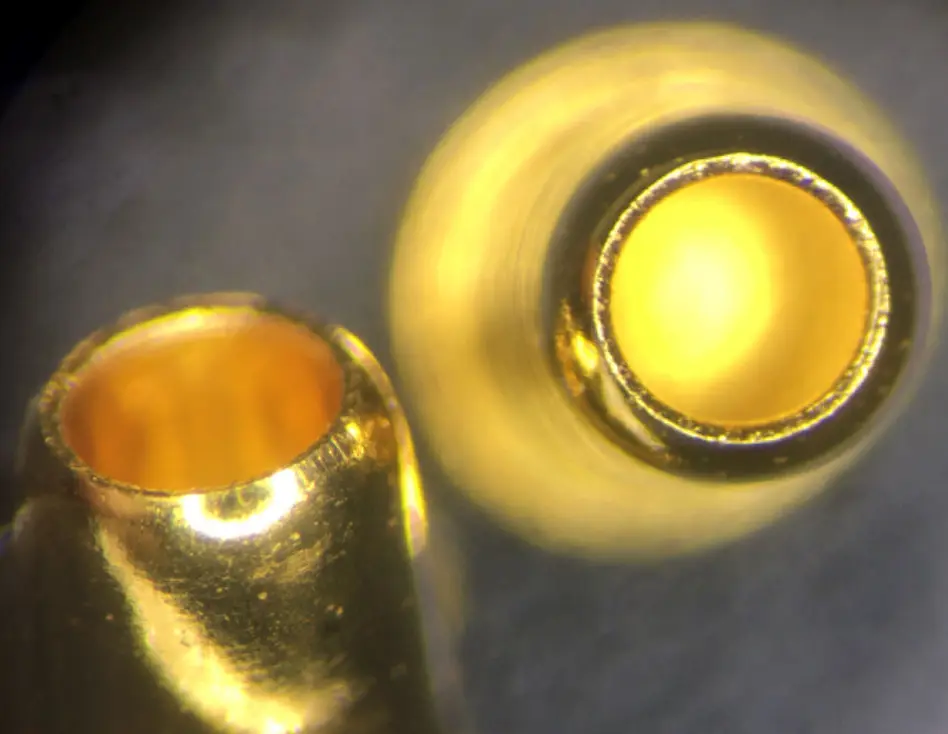

Vacuum blind hole plating technology is known for its excellent performance and can accurately plate a layer of gold inside and outside extremely fine blind holes. This advanced electroplating process not only ensures the overall beauty of the metal surface, but also provides excellent corrosion and wear resistance. Every detail, whether inside or outside the hole, shows a golden and shiny color, and there will be no peeling or gold falling off problems. The precision and stability of this technology ensure the durability and durability of the electroplated layer, meeting a variety of demanding application requirements.

Mature design, high-precision processing and advanced vacuum blind hole plating technology are combined to achieve extremely low and stable contact resistance.

| Items | Details |

| Material | ● Plunger: Lead-Free High Conductivity Copper Alloy |

| ● Body: Lead-Free High Conductivity Copper Alloy | |

| ● Spring: Lead-Free Stainless Steel | |

| ●SolidPin: Lead-Free High Conductivity Copper Alloy | |

| Main Technical Parameters | ● Standard state: |

| ● Operating temperature: -40~+180°C(Standard) | |

| ● Operating humidity: 20-85%RH | |

| ● Storage temperature: -10~+50°C | |

| ● Storage humidity: 20-85%RH | |

| ● Rating voltage: 36V AC/DC(Standard) | |

| ● Rating current: 10-30A/Pin Continuous(Standard) | |

| ● Contact resistance: 30 mΩ Max.(Standard) | |

| ● Withstanding voltage: 250V AC ,1 Minute | |

| ● Insulation resistance: 500 MΩ Min. | |

| ● Durability: 10,000 Cycle(Standard) | |

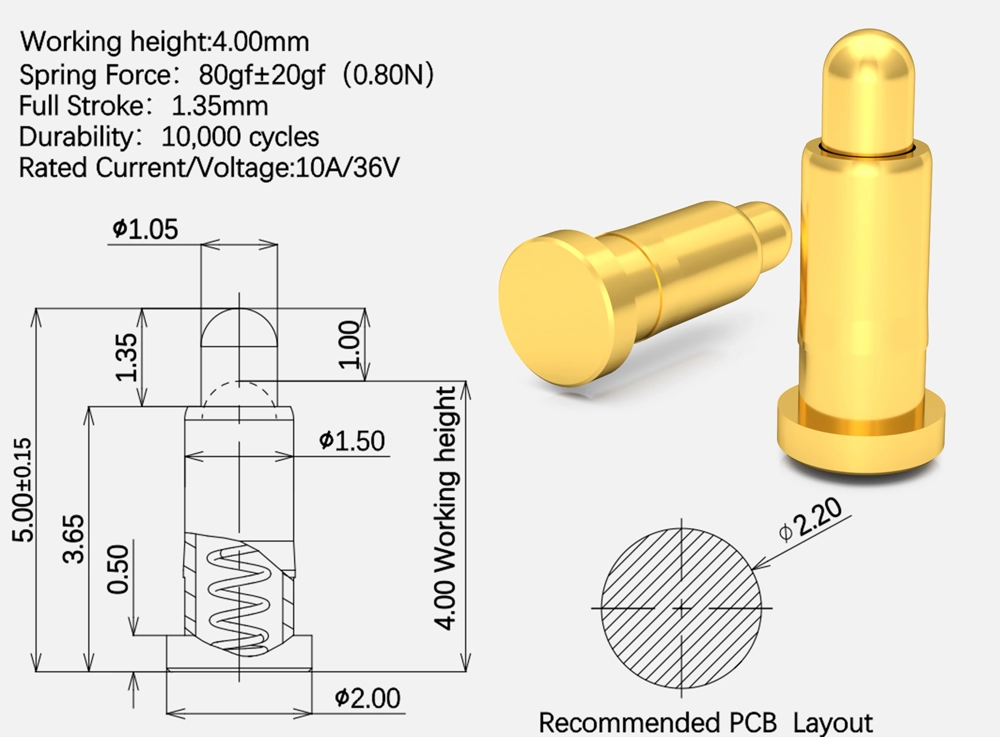

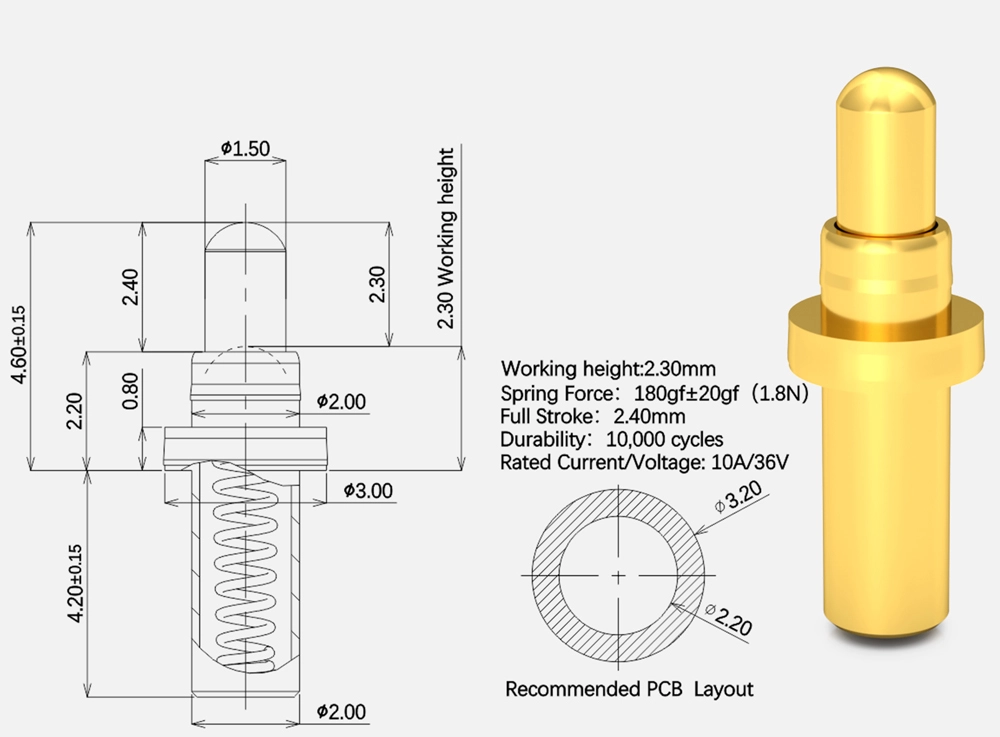

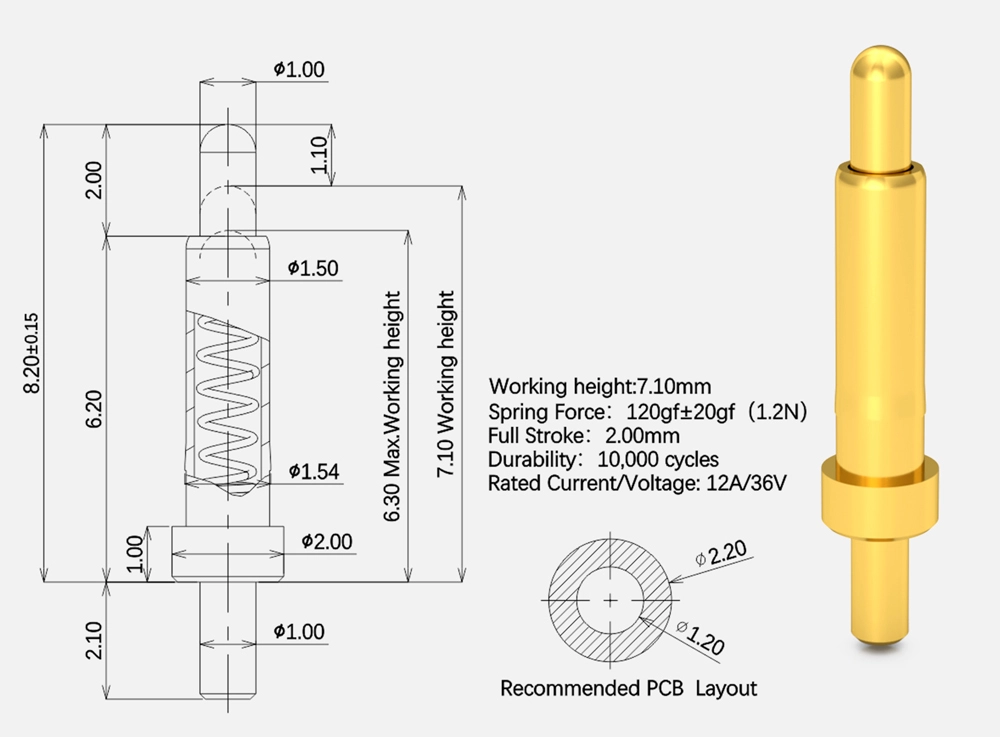

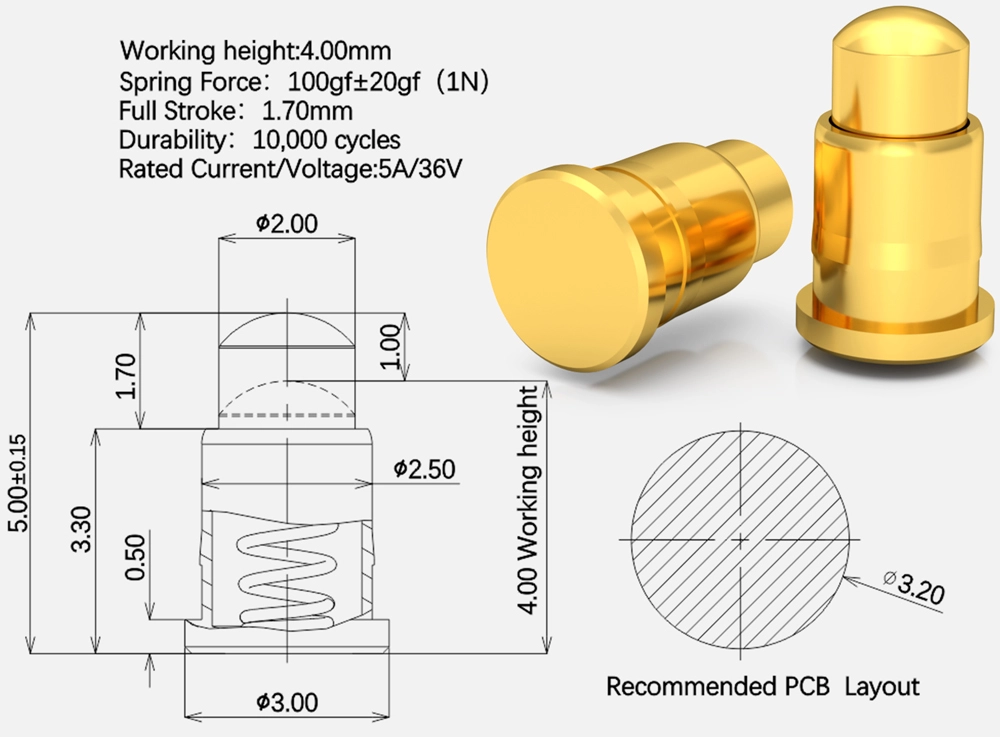

| ● Working Spring Force: 80~200gf(Standard) | |

| Electroplating | ● Plunger: Nickel Plating and Gold Plating |

| ● Body: Nickel Plating and Gold Plating | |

| ● SolidPin: Nickel Plating and Gold Plating | |

| Contact Type | ● Vertical Contact Type/Side Contact Type |

| Installation Method | ● SMT automatic placement machine+Reflow soldering |

| ● Plugin machine + Wave soldering | |

| Environmental Protection Standard | ● Comply with EU RoHS and Reach standards |

Please Note: Please refer to the operation manual for instructions and precautions

| SN | Product Image | Product Type | Initial Height | Working Height | Catalog Download |

| 1 |

| Flat-Bottom Type | 5.00~16.00 | 3.80~15.00 | High Current SMD Pogo Pin |

| 2 |

| Plug-in Type | 5.00~16.00 | 3.80~15.00 | High Current Dip Pogo Pin |

Contact

Rtench's Pogo Pin Connectors News